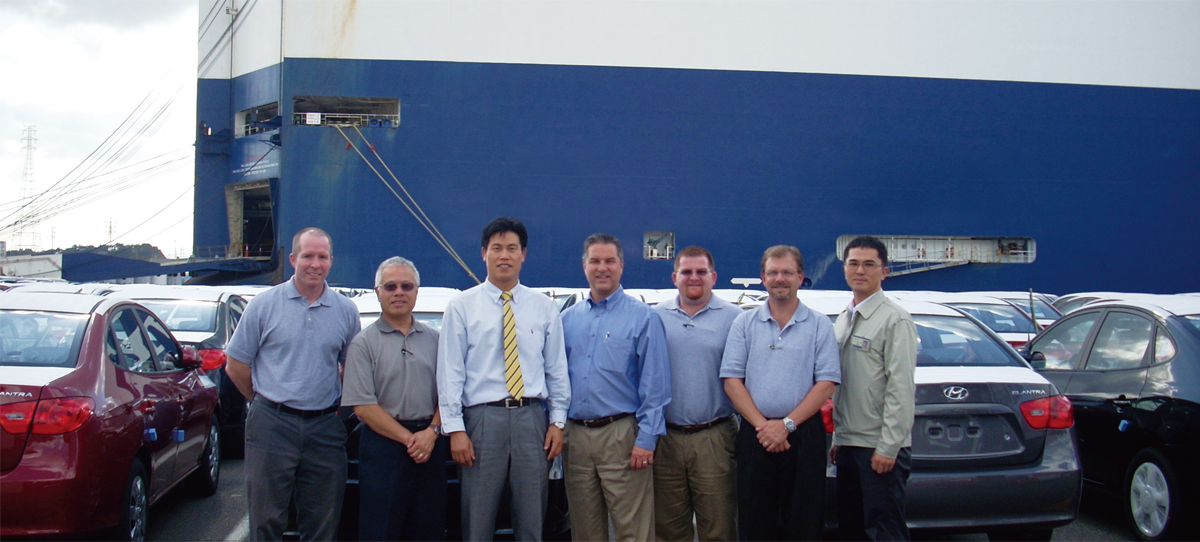

Hyundai Glovis valuable scene

Building a cornerstone for advancing into the world

Glovis America established in 2002

In November 2002, soon after the launch of Hyundai Glovis, Glovis America was established. Glovis America started business to support Hyundai-Kia Motors America’s local finished-vehicle logistics efficiency. As it was a new company, a lot of effort was required for initial setup and stabilization. Currently, they are stably operating various businesses in automotive logistics. Through steady expansion, it has been recognized as an undisputed integrated automotive logistics service provider in the U.S. market, and a company that many OEMs want to cooperate with.

That fact that the America headquarters was established in the USA, the main arena for competition in the global logistics market, in the early beginning stage of Hyundai Glovis, before it became a global logistics company, has made the employees feel proud to be members of a global logistics company. The fact that we have a business in the USA, the world’s largest market, has given us confidence that we need not fear any other country. Based on such confidence, Hyundai Glovis is expanding its realms by establishing corporations around the world.

That fact that the America headquarters was established in the USA, the main arena for competition in the global logistics market, in the early beginning stage of Hyundai Glovis, before it became a global logistics company, has made the employees feel proud to be members of a global logistics company. The fact that we have a business in the USA, the world’s largest market, has given us confidence that we need not fear any other country. Based on such confidence, Hyundai Glovis is expanding its realms by establishing corporations around the world.

Q. What was the cornerstone of growth for Glovis America to have its current status, and what are the elements needed for sustainable growth in the future?

However big a business is, it is work done by the people after all. I think the cornerstone for our growth was our employees. In particular, the initial set-up and stabilization was successful thanks to the blood, sweat, and tears of the first generation resident workers. Now that it has stabilized, we would have to fill the workforce with the locals to be able to grow in the US market. Therefore, the necessary element for sustainable growth would be the strong competency of local talents. In fact, the harmonious cooperation between the local talents and the resident employees creates great synergy. By sharing strengths and complementing weaknesses, we are achieving not only growth in numbers, but a substantial growth in the network and the system, etc. In addition, the importance of the system in logistics is increasing day by day, and the fact that we have our own system, and that the members have a systematic mind in external marketing is a powerful weapon.

Q. What was the situation like when you were assigned to Glovis America, and how has it changed now?

In 2007, when I first started working overseas, about thirty employees had to relocate the office every two to three years because we were leasing an office complex near Hyundai-Kia Motors USA. Currently, 191 employees are working in the Hyundai Glovis building in the central region of Irvine, California, and more than 1,200 employees nationwide. Having our own building is very helpful in doing business with other OE makers. Another big difference is that we have achieved great external growth of 400% through expansion of business to business (B2B) other than B2C (with customers), in addition to the doubling of Hyundai-Kia's share in the U.S. market compared to 2007.

Q. How has Glovis America developed until now, and what kind of activities are you currently working on?

Based on the experience and expertise in the finished vehicle transportation/processing business accumulated in the United States since 2002, Glovis America has been developing continuously and established Glovis Canada in Toronto, Canada in 2009, opened GAPS Philadelphia in 2010, and started a Mobis transportation business all over the US in 2015, established a processing base in Shreveport, Louisiana in 2017, and opened a new processing terminal in Southport in 2019.

In this process, we have established various business modules in each field of the automobile logistics business, and we are reflecting the needs of our customers through our self-developed systems and operational know-how. What is important is that the experienced professionals in each field have developed with us. Currently, there are various EV OEMs in the US, which are strong in manufacturing but weak in logistics. Therefore, we plan to expand our business areas by providing integrated services with these companies, with the people of Glovis America, based on the rich experiences and learnings as a company specializing in completed vehicle logistics.

Q. If there is a unique way of work or an organizational culture of the employees of the Glovis America, please tell us.

First of all, an autonomous working system is well established. The employees also strictly observe the 8-hour workday. Also, paperwork for reporting is very rare. Most of the discussions are conducted through e-mails, Teams, or oral meetings. When we have a meeting, we don’t sit according to the ranks, whoever comes first sits in the desired seat. Even if you are an executive, if you arrive late, you will have to bring a chair from the next room to sit down on. Even when you talk to your bosses, you can express your opinions clearly. It’s wonderful to see people concentrate on their tasks at work, and enjoy the time on their breaks.

Aside from work, we also enjoy holidays. Before COVID-19, we used to gather for Halloween or Christmas parties to celebrate the year’s hard work. We can also see people sharing chocolates and candies with each other. Although US is known to be a country where people are self-centered, we communicate actively and share our hearts.

Q. How is the work environment changing recently for COVID-19?

Under the assumption that COVID-19 isn’t going to end soon, we are preparing for a change of all office structures and work methods fit for a telecommuting environment. Meetings and communications are already mostly done through Teams. This approach is time- and money-efficient, and it has given us an opportunity to think about the precious things that we've overlooked when working face-to-face. When we were working in the same place, we used to know about the issues around us and how the company is doing by seeing people by chance and talking with them. The working from home will probably continue even when COVID-19 is over. Many American companies have implemented work-from-home before the pandemic, and the trend has been maintained. However, the non-face-to-face work method of work-from-home tends to reduce the sense of belonging or solidarity, so Glovis America is planning policies that can play to strengths of both online and offline.

Q. What is the future of Glovis America that you dream of?

Decentralization seems to be one of the trends of the times. Therefore, if the leadership of overseas business can be dispersed around Glovis America, which is in the United States, the world's largest consumer market and cluster of global companies, I think that approach to the global market will be more active. In addition, in the Hyundai Motor Group Investor Day announcement a while ago, they found the future identity in the mobility service company. I believe the group company closest to mobility service is Hyundai Glovis. Then we, too, will have to develop competencies suitable for it, and Glovis America will have to take the lead in paving the way.

Q. How important do you think the role of Glovis America is in Hyundai Glovis, and within the whole group?

Glovis America will be a very important criterion for Hyundai Glovis to become a truly global country. If we build an evolution model for overseas corporations referring to Glovis America, we will be able to stably work on both the globalization of the company and the localization of overseas corporations. Also, in the future, the era of the global village will come as boundaries blur. The recent trend is that people are understanding logistics as an investment for securing competitiveness and creation of added value. The e-commerce and mobility services pursued by leading global companies ultimately lead to logistics services. As a result, the status of Hyundai Glovis within the group is expected to rise further. Of course, to realize this, we need to think about ways to develop our current business models more creatively.

Full-scale KD logistics comprehensive service begins

HMMA KD business starts in 2004

HMMA(Hyundai Motor Manufacturing Alabama) is a fully localized factory built in the United States, and it is a comprehensive automobile factory that carries out the entire process of automobile manufacturing and assembly and testing. The KD business exports automobile parts. It receives domestic and foreign parts orders and delivers them to local factories. In order to successfully operate this business, it is important to reduce logistics costs, and it is necessary to secure stable production and a consistent supply chain.

This is the HMMA KD project that Hyundai Glovis participates in. It started for a local factory (HMMA), and it was different from the previous business in that the packaging specifications were developed considering optimized packaging standards; and a parts characteristics, system was developed for timely delivery, and field work

was standardized. By establishing the optimal standard for the KD business, HMMA was able to reduce costs by supporting the entire logistics supply chain from purchasing parts, and greatly improved efficiency by making it possible to check where necessary parts are located.

The reason why this project is receiving attention is because it provided an opportunity to dramatically improve the shortcomings of the existing process. Moreover, since it was a field that only Hyundai Glovis could carry out, it became an important turning point for them to gain expertise. With this business, which started a comprehensive service for KD logistics, such as packaging, transportation, local inland transportation, and storage, from orders from domestic and foreign parts companies after receiving orders from customers, Hyundai Glovis was able to start moving forward as a specialized automotive logistics company.

Q. What expectations did you have while participating in this project, and in what did you feel pressured?

At first, we started with Hyundai Motor's operating method, but we had the idea and expectation to create our own unique method. However, since we had no experience in KD, we felt pressured to set up the operation (system, organization, on-site operation, etc.) within a short period of time. So, in terms of parts supply, we worried a lot about whether the goods we send could really arrive at the local factory without any quality problems; and whether it would be possible to establish a stable supply system in a short time with little experience.

Q. How much of your initial expectations have you achieved?

In the early days, we could not have imagined the progress we have accomplished today. KD packaging technology is the specifications developed by us that is used by many parts makers. Our affiliates such as Hyundai Mobis are developing and using similar systems. Currently, we have built a global network to supply KD to 11 overseas factories, and we also perform production and logistics there, after the arrival. We are proud to say that we have achieved the world’s top system, technology, and operation in the automotive KD sector.

Q. What was the most difficult situation, and when was the most rewarding moment?

In the initial stage, there was a lot of trial and error in the system or the operations. We had to identify the problems one by one to deal with them. However, as we became more experienced, we became more skilled, and the system also stabilized. Things got settled. With the HMMA business of high expectations, the number of overseas corporations increased, and the settlement time also shortened. It felt rewarding to see that our customers depended on us increasingly.

Q. What are the activities of HMMA? And what can Hyundai Glovis do to help with it?

HMMA currently produces five models, and plans to start operating production lines for EVs by the end of 2022. Hyundai Glovis is promoting smart logistics by introducing an automated robot system in the KD center. For now, some of the manual work lines in the Asan KD Business 2 Center are converted into automated machines for test driving. We plan to gradually expand this and promote smart logistics by building automated lines from warehousing parts to loading at containers.

One-stop logistics completed with the start of sea transportation

Started marine transportation in 2010

In April 2008, Hyundai Glovis started the marine transportation of completed vehicles. It was an area that could not be easily approached as it required large-scale investment and professional competence, but Hyundai Glovis accepted the challenge to advance further as a globally integrated logistics company based on the logistics network it has built up over the years. At the time, it started with one small team of ten people. The transportation of completed vehicles was planned to start in 2010 in full-scale, so the team had to move quickly, taking care of tasks such as securing ships, responding to shippers, and operating ships, as well as contracting with agencies, issuing shipping documents, and registering companies.

As the marine transportation of vehicles was monopolized by a few shipping companies, Hyundai Glovis’ entry into the shipping market was not welcome news for the existing shipping companies. It was not easy to achieve the goal of increasing and expanding the supply volume of the affiliates, but it was also difficult to expand non-affiliated businesses due to checks from other shipping companies.

However, the fact that Hyundai Glovis directly exports finished vehicles as an affiliate in charge of Hyundai Motor's logistics had great significance not only for us but also for the group companies, and had a positive influence for the development of the domestic shipping industry. Hyundai Glovis made an effort to become the center of the market and is currently achieving satisfactory results. This business marked a significant milestone in the history of Hyundai Glovis in that it completed truly integrated logistics by successfully advancing into the marine transport sector, in addition to the logistics necessary for domestic production and abroad after arrival.

As the marine transportation of vehicles was monopolized by a few shipping companies, Hyundai Glovis’ entry into the shipping market was not welcome news for the existing shipping companies. It was not easy to achieve the goal of increasing and expanding the supply volume of the affiliates, but it was also difficult to expand non-affiliated businesses due to checks from other shipping companies.

However, the fact that Hyundai Glovis directly exports finished vehicles as an affiliate in charge of Hyundai Motor's logistics had great significance not only for us but also for the group companies, and had a positive influence for the development of the domestic shipping industry. Hyundai Glovis made an effort to become the center of the market and is currently achieving satisfactory results. This business marked a significant milestone in the history of Hyundai Glovis in that it completed truly integrated logistics by successfully advancing into the marine transport sector, in addition to the logistics necessary for domestic production and abroad after arrival.

Q. What were the difficulties you faced with this business, and how did you deal with them?

It was a business heavily checked, so it was difficult to secure non-affiliate supplies in the initial stages. We have been making efforts to increase non-affiliate supply volume through strengthening competitiveness in freight charges and services and forming close ties with shippers, and so forth. In the beginning, we made small-scale contracts rather than large-scale ones, but from the second half of 2010, we secured some large-scale, long-term contracts. In 2019, we secured a contract for transport from Europe to China for five years with Volkswagen, and recently we signed a contract worth 500 billion won per year for a global completed finished vehicle maker from China to Europe. These achievements were possible because all the members of the Shipping Business Group made efforts to provide the best service from their positions, and all related departments actively cooperated with them.

Q. How is the market formed, and what is the status of Hyundai Glovis like?

There are two shipping companies for completed vehicles in Europe, three in Japan, and one in Korea. These six major shipping companies provide global marine transportation services. Last year, we transported a total of 3.18 million units, the highest among these six shippers, and we expect to stay at the top in the global market with the transportation of 3.3 million units this year.

Q. What would be Hyundai Glovis’ know-how in this business?

I believe that our strength is, compared with other shipping companies, to flexibly respond to the shippers’ requests and provide a new service solution, outside the existing service framework. For example, by 2018, an American EV maker had been transporting its exports to Europe from San Francisco to the east of the country by inland route, and then shipping to Europe by sea. Accordingly, as we were transporting some of their shipments from the USA to China and Korea, we proposed to them a direct shipping service from San Francisco to Europe. With several trial shipments, we were recognized for our service competitiveness, and we have been officially operating the shipments from the first half of 2019.

Q. What will the market look like in the future, and how is Hyundai Glovis preparing for it?

Until now, vehicle shipping has mainly focused on heavy equipment including cars, but recently the cargoes being shipped are becoming more diversified. Due to the shortage of container ships, we are receiving a lot of inquiries about whether it is possible to use PCTCs for cargo that had been shipped on container ships. In order to actively respond to this situation, this year, we plan to establish a special cargo team for PCTCs to more actively carry out special cargo businesses, review shipments, and respond to shipper CS. In the future, we also plan to introduce new ships considering loading of not only existing cargo, but also various facilities and UAMs.

A stepping stone for a new leap

New businesses for the future, 2021

Hyundai Glovis is preparing for a new leap forward with promotions for new businesses for the future. The future businesses are largely divided into two areas, one is the smart logistics business, and the other is the eco-friendly energy business. Businesses in smart logistics include smart logistics solutions, e-commerce logistics, and platform-based transportation. In eco-friendly energy, the representative business is hydrogen distribution. We are also exploring other opportunities across the entire value chain, such as hydrogen fuel cell power generation, mobile hydrogen charging stations, and marine transportation of hydrogen. In addition, we are also reviewing battery collection and recycling business, UBESS business, and energy platform businesses using EV batteries.

Hyundai Glovis has continuously developed over the past 20 years. However, in the rapidly changing market, it is not possible to guarantee a sustainable growth only with the main businesses. Therefore, challenging for new businesses while the main business is flourishing would open the way to sustainable growth, and through this, it will be possible to prepare a starting point. With another leap forward to the new businesses we are preparing for the future, we will be able to open up possibilities to break away from the automotive logistics company and become an energy solution provider.

Hyundai Glovis has continuously developed over the past 20 years. However, in the rapidly changing market, it is not possible to guarantee a sustainable growth only with the main businesses. Therefore, challenging for new businesses while the main business is flourishing would open the way to sustainable growth, and through this, it will be possible to prepare a starting point. With another leap forward to the new businesses we are preparing for the future, we will be able to open up possibilities to break away from the automotive logistics company and become an energy solution provider.

Q. What kind of mindset do the employees who work on the future new businesses have, and what competencies do they need?

All employees who are promoting future businesses are working hard to develop their own new business and to bear fruit. The competencies needed for new business promotions is the understanding of the industrial environment of the field, professional knowledge in the domain, and experiences. In addition, imagination an adventurous mind, and quick response are also necessary. As you cannot work alone, networking with outside experts and partners is also important.

Q. Are there aspects that employees of other departments should know, or mindset they should have?

The Smart Innovation Division is preparing to discover the next wave (new growth engine) and achieve outcomes. We believe we are able to work on new businesses because there are other departments that are successfully carrying out main businesses. I believe that the company will have a turning point to make a quantum leap, if new businesses are successfully pursued. Therefore, rather than dividing the department into logistics/shipping/distribution/support, I wish they can think of them as one team. Although the main business division is in charge of current business and sales, and the SI is in charge of preparing for the future generation’s sales, they are cooperating with each other.

Q. Please tell us about your resolution for the success of the new businesses.

It is the new year of 2022. At the new year ceremony of the group companies, Chairman said, “We want to make the year 2022 a year in which the group’s efforts can be visualized and its potential realize into daily life of the customers.” Hyundai Glovis will have to keep up with it, too. Although it is difficult for new businesses to produce results immediately, we plan to make visible progress so that we can move forward in that direction by clarifying what we can show when we succeed.

Q. Please give some words of encouragement for colleagues who are working hard for new businesses.

I thank all the employees for their hard work in discovering new businesses since the establishment of the Smart Innovation Division in 2020. I hope that you will continue to work hard, as you have been so far, for new businesses in the future. Let’s make the year bear some fruits in the new businesses we are promoting.

2022.02.01