In honor of Hyundai Glovis’ 23rd anniversary, we’re celebrating with a special interview with three proud longtime Hyundai Glovis employees who have shared the highs and lows of their careers with the company. We take a look back at the past and remember the shining moments. We also look forward to the bright future of Hyundai Glovis, which is sure to sparkle once again.

![]() Tell us about yourself

Tell us about yourself

Hello, I joined the KD Business Strategy Team in December 2003 and am responsible for planning and supporting the strategy and direction of the KD business.

I joined the Hyundai Glovis on February 1, 2006, and have been with the company for 18 years. My team is responsible for transporting finished vehicles from the factory to the regional distribution centers so that they can be sold to customers.

(From left to right) Senior Manager Choi Jong-hoon, Vehicle Transportation Business Team,

Senior Manager Cho Han-Wook, PCTC Europe/Africa/Middle East Operation Team

and Senior Manager Shim Ju-Young, Auto Parts (KD) Biz Strategy Team

![]() What were you doing in 2001 when you founded Hyundai Glovis?

What were you doing in 2001 when you founded Hyundai Glovis?

I was in charge of RV sales management at Kia Motors. After only five years, I moved to a logistics company and never thought I would stay so long.

Farewell party for Hyundai Glovis employees in 2006

![]() How do you feel about the company’s 23rd anniversary?

How do you feel about the company’s 23rd anniversary?

In 2003, when I joined the company, we had sales of KRW 700 billion and about 100 employees. Today, the KD division alone has grown to KRW 9 trillion in sales and more than 170 employees. I am proud to be part of Hyundai Glovis, which has grown from a startup to a logistics leader.

In February 2006, when I joined the company, we had our fifth anniversary celebration, and I remember that the entire headquarters, which was about 150 people, gathered to clean up the Han River and rented a movie theater to watch a movie. Today, we have more than 150 people working on one floor, so it’s a great feeling.

![]() Do you have any funny stories from your time at Hyundai Glovis?

Do you have any funny stories from your time at Hyundai Glovis?

I worked as an expatriate for about 9 years, so I remember some of the things I did overseas. It was in India in 2009. After the financial crisis 2008, car sales picked up sharply in 2009, and Hyundai’s HMI plant was fully operational, producing 600,000 units. The volume was so high that we had to work non-stop, even at weekends. I also worked overnight two or three times a week. At the end of the year, I looked at the system operation record, and it was 352 days out of 365, minus 13 days. I remember being surprised to see that record.

I remember the first time I came to work and started my first business. When I joined the company in 2003, the KD business started in a small rented office in a stick factory. In March 2004, we received our first order from customer, and it was very difficult because we didn’t have a packing house, system, or packaging infrastructure. We didn’t have a dedicated business system, so we had to source parts the hard way, faxing and calling over 120 vendors with purchase orders I’d spent all night creating in Excel.

At that time, the volume was low, so the parts companies sent a lot of goods by courier. I received so many packages that two years later, the Group Business Improvement Team asked me what these packages were, and I submitted a fact check because it was misunderstood as fraud. I laugh now because I can’t imagine how they could have misunderstood it.

“I think it was July 2014, and there was an auction of a PCTC in a Belgian court. We participated in the auction and were able to secure one of the ships that we are currently operating. It’s not a funny story, but it’s a rare experience, so it still sticks in my mind.”

– Senior Manager Cho Han-Wook, PCTC Europe/Africa/Middle East Operation Team

![]() What was a time when you grew both professionally and personally?

What was a time when you grew both professionally and personally?

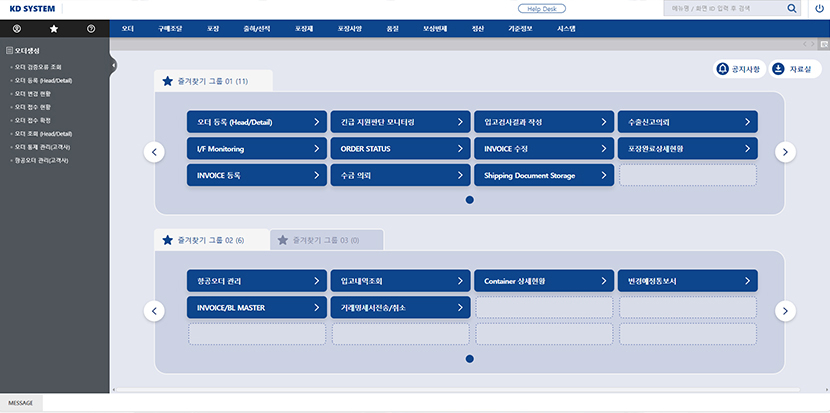

We started the KD business in April 2004, but the turning point for the real growth of the KD business and staff was in 2005. In 2005, we developed our own CKD web system specialized for Hyundai Glovis, and built and operated a system to manage the entire logistics of ordering, receiving, packing, and shipping. In May of that year, we completed the Asan KD Center, which enabled us to operate KD through our logistics infrastructure. I think it was around that time that we secured the capabilities of the Hyundai Glovis KD business.

Inside and outside of the Asan KD Center 2

I came to logistics from the automotive business, so it was completely new to me. In 2008, I came to India for the first time and set up the transportation of finished cars. At that point, as we developed the system, I gradually understood the system and realized that this is what logistics is like. And in 2009, when the volume increased, we tried to handle the volume somehow. So, we built up our know-how and skills. I personally grew a lot from that experience. I think it was the first company, I think it was 2011 or something? I also remember that we were the first company to invest directly in automotive TP and we had 30 cars locally.

It was the most beneficial time for me and I would highly recommend young people to go as an expatriate because it’s a great opportunity to build on that experience and further their personal development. They’re going somewhere that requires new work or infrastructure setup, so they can have a better experience.

The company was founded in 2001, but in the case of the cubicle I was working in, I probably started the company in 2010, and I think the first two years were probably the most learning and growing period of my professional life. Because usually when we go into an organization that’s stable, where everything’s already built, you’re doing the work that you’re assigned to do, so your scope of work is not that broad, and then you’re thrown into a phase where you have to start from scratch with a lot of things. I had to deal with new things on top of my existing duties, so I had to go through the process of finding the right person to ask and resolve anything I didn’t understand, and I think that’s when I really improved.

![]() Were you even convinced that Hyundai Glovis had a vision?

Were you even convinced that Hyundai Glovis had a vision?

” In the early days, we had a lot of different cultures because people came from different companies., but over the course of five or 10 years, we started to have happy days, and it really brought the whole organization together, and we saw that we were building infrastructure through investments like investing in the car line, and we saw that this company was going to get bigger and bigger and become a global logistics company.”

– Senior Manager Choi Jong-hoon, Vehicle Transportation Business Team

![]() What was the shining moment of your life with Hyundai Glovis that made you realize, “I’m so cool!”?

What was the shining moment of your life with Hyundai Glovis that made you realize, “I’m so cool!”?

The first time I realized the value of my work in the KD business was when I went on my first overseas business trip. When I was overseas, the KD parts we shipped were unpacked from the containers and stored in the CC of the factory, and they were moving non-stop to be put into the production line. When I saw the finished car made from those parts on the assembly line, I felt very rewarded and proud.

Every moment of completing the task was rewarding. Personally, as an expatriate, I was on an expatriate assignment to India and Russia, and the non-English speaking nature of these two regions meant that communication was quite limited. but I tried to show my sincerity. At events such as year-end parties, I would write down Indian or Russian speeches in Korean and read them to them, which local staffs enjoyed. We had built trusting relationships with local carrier representatives by treating each other with respect.

When I left India, I had the experience that representatives of all the carriers in India came together in a city called Chennai to give me a farewell party, and I think that was one of my proudest moments as an expatriate and in a small way as a civilian diplomat, as I boarded the plane back home knowing that I had fulfilled my responsibilities.

In the Hyundai Glovis Russia, Senior Manager Choi Jong-Hoon organized a Women’s Day event

![]() Tell us about something you’re proud to have contributed to the company’s growth

Tell us about something you’re proud to have contributed to the company’s growth

“Everything in the KD business is done through the system. We receive orders from overseas factories, order, receive, pack, and ship based on the orders. All logistics information is exchanged with overseas factories in real time. The system is very important. The CKD web system we developed in 2005 was 17 years old and outdated and needed to be rebuilt.

I spent six months preparing for the system implementation and 18 months working on the project, and in June 2023, we opened the new KD system. There were many difficulties due to the complexity of the KD business and issues related to other systems, but with the help of the KD Business Division members, we were able to successfully complete the project.

When quality was lacking, we were able to find defects and ensure quality through seven rounds of integrated unit module testing. I would like to take this opportunity to once again thank all the members of the KD Business Division who participated in rebuilding the KD system.”

– Senior Manager Shim Ju-Young, Auto Parts (KD) Biz Strategy Team

During my time in Russia, from 2014 to 2018, there was a significant emphasis on northern logistics. Our company also made considerable efforts to pioneer the TSR route, and I had the experience of transporting small quantities on the connecting TSR route. I also remember consulting with the packaging technology team in my home country to develop packaging materials that could withstand the shaking caused by rail transport for more than two weeks.

Although the project is currently suspended due to the international situation, if there is a day when northern logistics via the TSR route is revitalized in the future, I will feel quite proud and proud that the efforts of my colleagues and I were able to lay the foundation.

Our company invested in a total of 23 vessels from 2010 to 2015, and about 15 of them are what the shipping industry calls post-Panamax size vessels. Panamax typically refers to the maximum size of ships that can pass through the Panama Canal. In 2016, the Panama Canal was expanded to create a wider sea lane than the existing canal, and post-Panamax refers to ships that can pass through it. At the time, our peers and carriers were a little hesitant to invest in post-Panamax ships, but we were very proactive. It was also the largest car carrier in the world when we ordered it.

Post-Panamax vessels in which we were a leading investor

And when you invest in a vessel, you have to have cargo to transport, and I think it was around 2015 that we started with a small cargo contract, which I mentioned earlier, in 2012, and then we started with a large cargo contract, which was around 2015. We had a contract with one of the big three German manufacturers, and then in 2016 and 2017 we had a series of contracts with American manufacturing companies, and I think that was a big foundation for Hyundai Glovis to grow to where we are today.

![]() What are your plans for the next 20 years?

What are your plans for the next 20 years?

Over the past 20 years, our KD business has grown with Hyundai’s manufacturing footprint, starting with the HMMA plant in Alabama in 2004 and continuing with investments in overseas plants such as the Czech Republic, Slovakia, Georgia and Mexico.

We are preparing for the next 20 years to be a time of spontaneous growth for KD. We have selected three priorities to create future growth engines. The first is to expand KD’s business. We are pursuing business expansion such as TA CKD orders and unaffiliated sub-KDs. The second is center automation. The packaging area of the KD business is labor-intensive. As the population decreases over time and labor costs increase, we expect difficulties. We are introducing new technologies to automate Hyundai Glovis centers to improve labor efficiency and prepare for rising labor costs. Finally, we are conducting VE activities through our own packaging technology and capabilities acquired over 20 years. These activities are designed not only to improve our own profitability, but also to meet our customers’ needs and provide better service. We will continue these activities.

Like other industries, climate change is a hot topic and a challenge for the shipping industry. In 2023, the Carbon Intensity Index, or CII for short, will come into effect, and this year is the first year of the EU Emissions Trading Scheme, which calculates the carbon emissions of ships sailing to Europe and requires us to buy credits for that amount. These regulations are not limited to one or two years, but the scope and degree of regulation is gradually expanding and intensifying with each passing year. So we have to address the environmental issues of shipping as a mode of transportation.

We have ordered a total of 24 dual-fuel LNG ships in the last two years. This is a minimal investment in response to CII or EU ETS, but I think we should be actively looking at investments in other marine fuels, not just LNG.

A team of automotive pioneers united by passion and ambition

I think it’s similar to what Senior Manager Shim Ju-young said, that the first 10 years was the phase where we entered the business, established each base, participated in the business and launched it, and then the next 20 years was a period where we really improved our capabilities and expanded our role.

Now, looking ahead to the next 10, 20 years, I would like to see us enter a period where we more aggressively build our own infrastructure and operational capabilities and lay some kind of foundation as a true logistics company. I would like to see us secure our own infrastructure a little bit more so that we can regain our reputation as the best logistics company in Korea and even globally.

![]() What would you like to say to the people who were with you or supported you during that rewarding and glorious moment?

What would you like to say to the people who were with you or supported you during that rewarding and glorious moment?

The KD business has 3 departments and 12 teams, and it is only when each of them performs well that we can provide good quality and timely supply. Therefore, I would like to thank my colleagues in the KD Business Division who have been with us for 20 years.

KD Business Division’s Fun Time

Vehicle Logistics Group has led the company as a key industries, and all of our employees are proud of this and work together as a unified team. First of all, I would like to thank all of our employees, from Director Kim Chang-ki, who has been here before, to Manager Park Jong-yeol, Manager Lee Kyung-joon, and Manager Hwang Byung-yong, who recently joined the company, who have always stood by my side and helped me when I was in trouble or in need.

I would also like to express my indescribable apologies and gratitude to my family, who traveled overseas with me… and to my wife and children, who struggled to adapt to every change in the environment.

![]() What words of encouragement do you have for Hyundai Glovis as it reaches the pinnacle of its life?

What words of encouragement do you have for Hyundai Glovis as it reaches the pinnacle of its life?

We started as a logistics startup 23 years ago, became a fast follower, and now a logistics first mover. We hope to become a better logistics company with a fuller inner life, just as we have grown nicely on the outside.

I think we’ve done a good job of overcoming the challenges and doing well, and as I said, all of us who have grown the business in the process of creating a culture of people from each company, we’ve done a good job and we will do a good job in the future, so I hope we can trust that and our colleagues and give it a good shot, and as the CEO always says, I hope our employees and our partners can come to work in the morning and go home safely at night.

Writer Editorial Department Photo Lee Bo-young Video Biboho Studio

2024.02.21