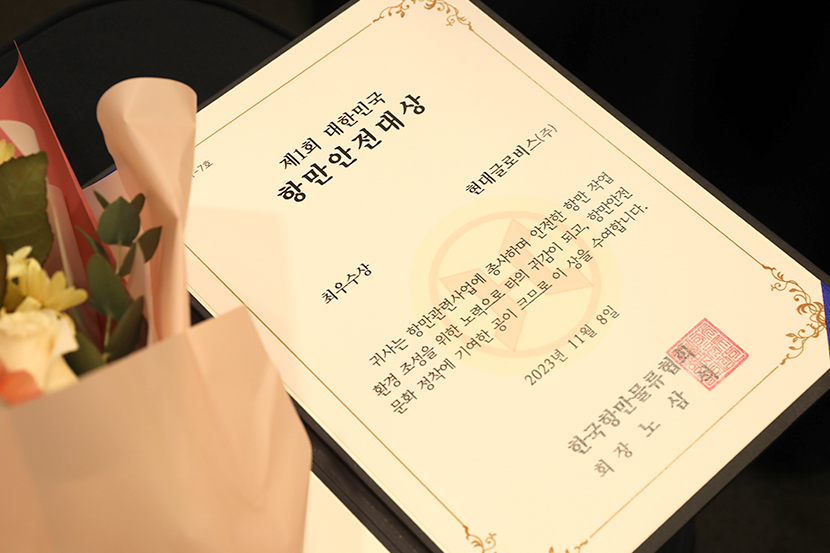

Safety is paramount at logistics sites. Port safety is also becoming increasingly important, and Hyundai Glovis won the best prize at the 1st Korea Port Safety Awards. The company was recognized for establishing a safety, health, and environment management policy and actively carrying out activities to implement it. Let’s take a look at Hyundai Glovis at the ceremony of the 1st Korea Port Safety Award 2023.

Hyundai Glovis won the best prize at the 1st Korea Port Safety Awards, which will be held for the first time in 2023 to inspire safety in the Korean port industry, for its contribution to preventing stevedoring disasters and for its safety prevention practices. Hosted by the Korea Stevedoring and Logistics Association and organized by the Korea Shipping Times, and sponsored by the Ministry of Oceans and Fisheries, the Korea International Trade Association,

and the Korea Shipping Association, the 1st Korea Stevedoring Safety Awards are designed to encourage companies, organizations, and workers who have contributed to the prevention of stevedoring disasters and to inspire compliance with safety regulations by identifying and recognizing best practices in safety prevention, as legal and social demands for safety in port workplaces are increasing due to the implementation of the Serious Accident Punishment Act and the Special Act on Port Safety.

The award ceremony, held on November 8 at the Korea Press Center, was attended by 16 winners, including four grand prizes, eight first prizes, and four second prizes, as well as officials from the Ministry of Oceans and Fisheries, Korea International Trade Association, Korea Shipping Association, and Korea Shipping Newspaper. Hyundai Glovis was represented by Kwon Chi-oh, Head of Terminal Operations Team. The winners received a citation from the Minister of Oceans and Fisheries and a cash prize of 3 million won for the Grand Prize, the President of the Korea Association of Port Logistics and a cash prize of 2 million won for the First Prize, and the President of the Korea Shipping Newspaper and a cash prize of 500,000 won for the Second Prize.

List of winners of the 1st Korea Port Safety Award

| Classification | Winners |

| Grand Prize (4 people) (Minister of Oceans and Fisheries Award) |

CJ Logistics Kim Min-ki, Head of Busan Port Workers’ Union Senior Manager Nam Jae-il, HMM Director Cho Jeong-soo, POSCO Flow |

| Best Prize (8 winners) (Korea Port Logistics Association President’s Award) |

Busan New Port Terminal HMM PSA New Port Terminal Incheon Container Terminal Chairman Park Kyung-il, Dangjin Port and Harbor Workers’ Union Director Kim Jae-gon, Gwangyang Port and Harbor Workers’ Union Deputy department head Lee Kyung-woo, Incheon Port and Transportation Workers’ Union Hyundai Glovis Team Leader Lee Wan-beom, Lotte Global Logistics |

| Excellence award (4 people) (Miritime Press President’s Award) |

Director Heo Inkyu, Sun-kwang Gunsan Branch Director Oh Hyun-soo, Port Safety Research Center Kang Dae-sik, member of the Gyeong-nam Port Workers’ Union Liaison Officer Shin-myung Kang, Chungnam West Port Workers’ Union |

“We’ve worked through a lot of challenges with the relevant departments and team members to create a safe harbor, and it’s rewarding and gratifying to be recognized in this way.”

Director Kwon Chi-oh, Shipping Business Strategy Group, attended the Port Safety Award ceremony on behalf of Hyundai Glovis. He expressed his gratitude for the award by giving credit to the relevant departments and team members. He analyzed three reasons why Hyundai Glovis won the best prize in the Port Safety Award competition. First, there are 31 trading ports and 859 berths in Korea (as of 2020), of which we operate four berths at two ports, Pyeongtaek-Dangjin Port and Gwangyang Port. Although our scale is small compared to other stevedores, we were able to win the award because we were sincere about safety. Second, based on our advantages as a terminal operator and a shipping company, we were able to establish an industrial accident and safety response system that organically involves all companies involved in stevedoring (shipping, stevedoring, berthing, inspection, inspection, inspection, and stevedoring), which created many synergies. Lastly, we hold a monthly port safety and health council with all related companies to share our safety policies, listen to their concerns, and actively reflect them. Through this, deep trust has been formed between each other, enabling us to build a more effective and safe workplace environment.”

“‘Safety first’ is a phrase we hear a lot, but in reality, I don’t know if everyone has a culture that prioritizes safety. In contrast, our culture of valuing safety and investing in safety was established early on, even before the enactment of the Heavy Traffic Act, which I think is a big driving force in creating a safer workplace and an advantage over other companies.”

A new appreciation for the power of coffee truck

As a part of creating a mature safety culture and encouraging employees, Hyundai Glovis runs a Safety Day campaign on the 27th of every month. In July 2023, Pyeongtaek Terminal was selected as an excellent safety workplace and received coffee truck as a reward.

“When we first started the campaign, I think some of the site workers perceived it as a coffee day, but after more than a year of campaigning, I realized one thing: creating a safety culture at the port starts with ‘reaching out’.In fact, when we approached the site workers and offered them drinks, listening to their pain points and empathizing with them, we could feel that they were paying more attention to safety than usual from then on. Even after we were selected as a ‘SSONDA’ site and offered coffee tea to the site, we could not help but be surprised to see that a safety culture was created for more than a month. We would be grateful if you would continue to send us more coffee truck in the future.^^”

Creating a safe environment by identifying, eliminating, replacing, and controlling risk factors also contributed to the high score, according to director Kwon Chi-oh. “In accordance with the Fourth National Port Master Plan, Gwangyang International Terminal completed the relocation of the pier from Phase 3-2 to Phase 2-1 as of October 1 this year, eliminating risk factors.

“Earlier this year, when we were preparing to relocate the pier and saw an empty site of about 450,000 meters2 , we had a lot of worries and concerns about how to make our workplace safe. In the end, we decided that the answer was on site, so we held many idea meetings with our employees on site for several months to identify hazards and find ways to improve our work processes to make them safer. Thanks to this, we were able to finalize the pier move without any major

problems, and we will continue to move forward to build an even safer working environment.”

Director Kwon would like to thank his team members and suppliers for their many improvement ideas for workplace safety. However, he has also received some cold shoulders from suppliers when conducting emergency response drills related to safety. He recalls the difficulties he faced when he conducted an emergency evacuation drill with all the workers in the port, assuming that a fire had broken out on one of our ships.

“Preparing for the drill was more challenging than conducting it, especially since we were trying to fit the drill into the ship’s berthing schedule, which ended up being rescheduled five times. With about 200 workers in the port, I don’t have to tell you how many eyes were on us. Fortunately, the drill went off without a hitch.” Director Kwon also analyzed that the continuous support and monitoring of suppliers to ensure safety and health is working. Until about a year or two ago, when listening to suppliers’ opinions on safety, there were many words such as “I want to do it, but I don’t know,” “I don’t know what to do,” and “Please tell me, how to do it”, but now it has changed. When evaluating suppliers, he said, the company has created an atmosphere of gratitude by informing them rather than criticizing them and showing sincere concern. In addition, by utilizing monthly safety and health council meetings to discuss safety-related issues and provide various safety information, safety awareness has improved to a very high level.

Safety is about making sure your coworkers can see you tomorrow!

“With the increase in social interest in safety and the new and revised laws, it seems that we have been running with all our might for port safety management. We have always demanded perfect safety management from our on-site safety managers, but now that I look back, I think, ‘The on-site safety managers must have suffered a lot,’ so in the future, in addition to continuous safety enhancement activities, we will try to find and implement measures to relieve the stress and motivate the safety managers who play a central role in on-site safety management.”

Mr. Kwon reveals his plan to take care of safety managers first when it comes to creating a safe and healthy environment. Finally, he concluded the interview by sharing what he would like to tell Hyundai Glovis employees about safety.

“There’s a line in the drama “Misaeng” that goes something like this: “Mr. Jang, I’ll still see you tomorrow.” I think safety is more important than anything else, even more so than making sure I can see my coworkers tomorrow. I would like to ask all Hyundai Glovis staffs to pay attention to safety so that I and my coworkers are not exposed to dangerous conditions.”

By Editorial Department

2023.11.21