The North America Forwarding Operation team works organically with the Hyundai Glovis local network and entities to fulfill export volumes in the Americas and bring goods from around the world to North America. How does the North American Forwarding Ops team handle the busy holiday season?

The North America Forwarding Operation Team strategizes, operates, and manages the smooth transportation of goods from Hyundai Motor, Kia Motors, and other affiliated companies, parts suppliers, and third-party customers to their destinations in the United States. The U.S. is the most important region for the Group and the Company in terms of current market size and future expansion potential. The U.S. is a “land of opportunity” with strong automobile sales and the continued establishment of EV factories, battery cells and materials factories, all of which are related to the trucking business.

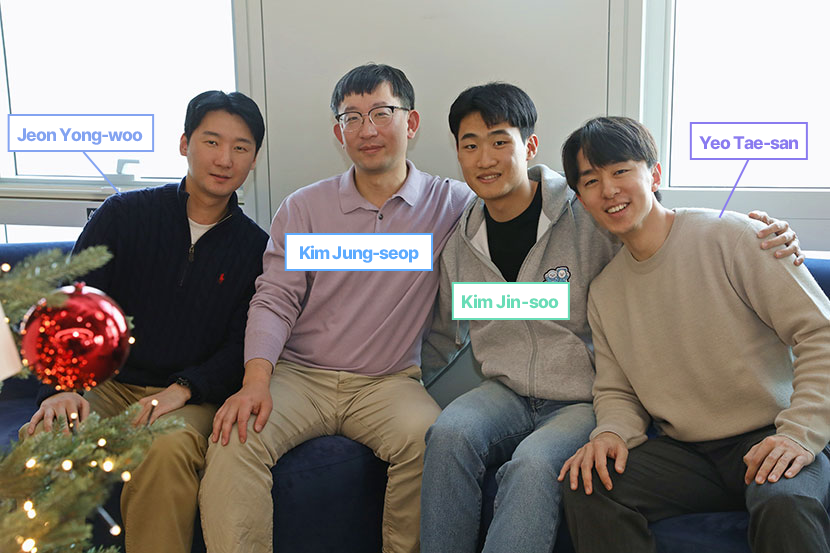

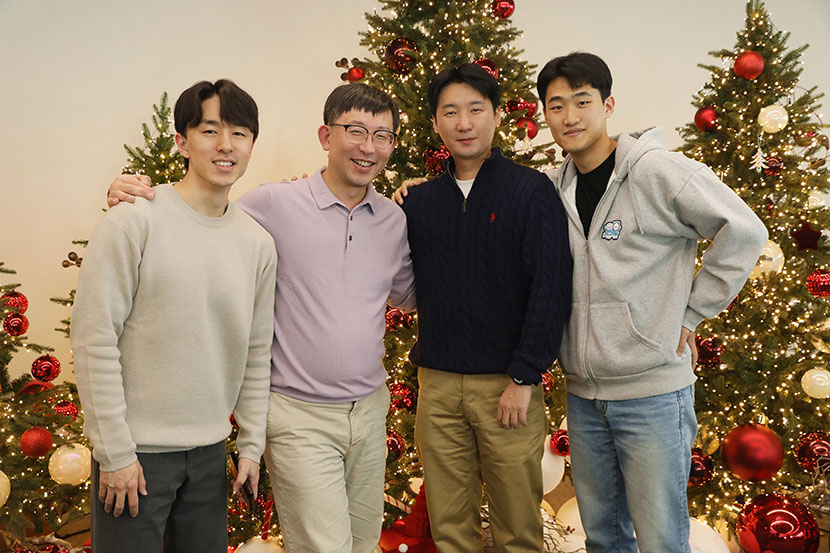

The North America Forwarding Operations Team is divided into North America KD and Group Companies, North America Mobis, and TPL Export WG, and consists of 25 members, including team leader Kim Jong-seop. Kim, who is in charge of the North America Forwarding Operations team, believes that the team has coped well with the changes in the logistics environment in 2023.

“It is rewarding when our customers thank us for identifying future risks and being proactive. In such cases, it takes a team effort to respond in unison, and I think the experience of being in sync and having a good process and outcome is a virtuous cycle that makes the team stronger.”

A fundamental part of the forwarding business is to communicate closely with the local people, overcoming time difference and language. Due to the time difference with the Americas, we often start video conferencing around 7 a.m. KST, but the next day everyone was on time for the meeting, showing the professionalism of the North America forwarding operation team.

The North America Forwarding Operation team is winding down for the year, reviewing the year’s work and organizing to make sure there are no problems with changing contract carriers or partners. Team leader Kim Joong-seop said that in 2024, the team plans to move more efficiently than this year and “take over” the Americas.

“The environment for export logistics to the Americas in 2024 will be challenging. I want to build a team that is more organized and efficient than this year, and most importantly, create an atmosphere where team members feel more connected to each other and have more fun at work.”

(from left) Senior Manager Jeon Yeong-woo, Manager Kim Jin-soo, Manager Yeo Tae-san

![]() Please tell us about yourselves.

Please tell us about yourselves.

Hello. I am in charge of the Mobis North America WG. In addition to exporting mass production products to the Mobis factories in Georgia and Alabama, I’m also responsible for exporting factory equipment to the new Mobis North America EV factory.

Hello everyone. My name is Kim Jin-soo and I am in charge of the Hyundai Transys account in North America for Forwarding Operation Team KD and Group Company WG. I operate sea and air freight from Korea to the Hyundai Transys plant in Georgia, USA. In addition, and I’m a hybrid (!) operator, I’m also in charge of some Hyundai Mobis AS parts cargo that is shipped by sea to the western and central regions of the United States.

I am Yeo Tae-san, Manager of TPL Export WG, North America Forwarding Operations. I am in charge of container exports for TPL customers outside of the group. It’s been a busy year for my team as we’ve been tasked with loading and exporting GM’s finished vehicles in containers, which has become a major new contract.

![]() What does the America mean for your freight forwarding business?

What does the America mean for your freight forwarding business?

The America region has a large sales volume and a significant market size. At present, there is a very high potential for business expansion in electric vehicle exports, such as the construction of the new HMGMA factory and the MOBIS EV factory, so I think there is a high potential for growth not only in the present but also in the future.

I feel the same way. It’s just the sheer size of the U.S. and how much influence it has on the forwarding business in terms of exchange rates, foreign policy, economic policy, and so on.

As the youngest line on the team, I can tell you from my short experience of two and a half years that North America is as short as one day by air, as long as 11 days by sea to the U.S. West Coast, and as long as 40 days through the Panama Canal. There is also rail to the interior of the United States and emergency trucking from the West Coast to the East Coast. It’s one country, but depending on where it goes and how it’s shipped, the transportation and lead times are as different as if it were going to and from multiple countries and continents, so I think there are a lot of points to manage and study as an operations person.

![]() Please describe the main responsibilities of the WG you are in.

Please describe the main responsibilities of the WG you are in.

The Mobis WG is divided into three sections: modules, service parts and AP. Modules are mass-produced parts that go into the factory line, so there are only two plants, Alabama and Georgia, but timeliness is very important, and AS parts are literally aftermarket parts, so there is a margin in terms of urgency and delivery time compared to mass-produced parts, but the difference is that the parts are exported to PDCs (Parts Distribution Centers) in different parts of the United States. In the case of AP, the volume is not large because it is exported to a third-party automaker, but it is characterized by the diverse nature of transportation, such as exports between the three countries. In addition, our WG has recently added the work of the equipment volume required for the new Mobis electric vehicle factory in North America, which began exporting in earnest around October this year.

KD Group company WG is primarily responsible for the transportation of freight that enters the lines of North American production facilities such as KD Parts, Hyundai Transys, and Hyundai Wia at Hyundai and Kia plants in the United States. Since there are many cargoes that are affected by the production schedule of the lines, my team is often asked to transport them urgently at the last minute, and it is our job to hold frequent meetings with the US site and ensure that the transportation is closely coordinated with the production schedule. It’s a small WG of 4 people, including myself, but we’re like small, hard kernels with a lot of volume that is diligently handled by each factory representative on a per diem basis.

The TPL Export WG is responsible for exporting to TPL customers other than Group companies. Our customers are mainly divided into two categories: auto parts companies and pure TPL customers. The former are companies that produce parts for finished vehicles, while the latter consist of various other customers such as chemical companies and paper mills. My WG is responsible for all aspects of safely and expeditiously transporting these customers’ freight to their designated locations.

![]() What are the recent issues related to your work?

What are the recent issues related to your work?

The Panama Canal drought has been in the news a lot lately, probably more than any other issue. The Panama Canal relies on adequate rainfall to raise the water level to allow many ships to pass through, and since the first half of this year, the drought has been ongoing, severely limiting the number of ships that can pass through each day. We’re already seeing some shippers rerouting through the Suez Canal, so this is something we will be monitoring as a top priority over the next year to find alternatives.

That’s right. Shipping from Asia to East coast of North America requires passage through the Pamana Canal to reduce the number of transit days, but as the drought continues, shipping restrictions are increasing. We are looking at solutions from different angles, such as monitoring the transit situation and diverting to other routes.

Last fall, a container truck carrying Hyundai Transys caught fire and overturned in the United States. As soon as we were contacted in the U.S., I had to scramble to ensure the safety of the local truck driver, expedite the transportation of a replacement for the damaged cargo, and handle the insurance claim. It was an unexpected accident and I didn’t know much about it, but my team seniors were very helpful and I used the crisis as an opportunity to learn about cargo insurance and accident handling.

![]() How do you handle emergencies in the workplace?

How do you handle emergencies in the workplace?

First of all, I think it’s important to share quickly with the people involved, because if you delay sharing because you’re worried about getting blamed or making it bigger, you often make a bigger problem out of something that could be easily solved. Also, when sharing, I believe it’s better to ask, “I have this emergency and I think I should respond this way, but what do you think?” so that the people involved can make decisions more quickly.

I tend to try to stay calm in emergency situations and organize the flow and outcome in my head as much as possible. I think it worked well because I figured out what I could control, whether customers and suppliers could cooperate, and what I didn’t know, asked my seniors for advice, organized everything down to the expected outcome, and put my response plan into action.

![]() What are your priorities in terms of organic connections with local entities or customers?

What are your priorities in terms of organic connections with local entities or customers?

Because of the time difference and distance, I rarely communicate with the local offices in person or by phone, but mostly by email. If the local representative asks for further clarification on something I’ve sent, they have to wait an extra day for my reply due to the time difference, so I try to be as detailed as possible in the first email to avoid additional questions. When it comes to connecting with my counterparts, I find that it works best when I see them often. I find that face-to-face time builds rapport and helps us work better together.

To ensure that our customers and partners feel reassured, I try to keep them informed as quickly and accurately as possible about the most basic, but potentially most sensitive things, such as shipment rescheduling and lead-time impacts. Even a week’s delay in the shipping schedule can often result in urgent transportation requests, so I try to communicate as much as possible to ensure that the schedule is still on track, and if there is even the slightest hiccup, I try to talk to the customer’s representatives to find a solution.

I’m committed to meeting our customers’ needs and providing them with friendly service. Our customers rely on us for logistics services, so I make it a priority to provide them with flawless logistics services, including securing vessels and managing transportation schedules. Along the way, I add a dash of hospitality to build stronger, more organic relationships with our customers.

![]() When do you feel rewarded for your work?

When do you feel rewarded for your work?

As an operations team, our work is concentrated during the billing deadline period at the beginning of each month, especially during the three days of the deadline, which often requires everyone on the team to work overtime. But the irony is that during this time, when we’re busy with day-to-day operations, it’s rewarding to look at the profit and loss of the month’s shipments and think, “Wow, that’s a lot of shipments I was responsible for in a month, and how did I make it through another month?

The most rewarding part is hearing from customers that they are satisfied with Hyundai Glovis logistics services. It’s a great feeling to know that my efforts are recognized and appreciated. lol

It’s rewarding for me to solve problems that I thought were almost impossible, one at a time, and to get good reviews and thanks from internal and external customers. Because of the nature of the forwarding business, you never know when a problem will arise, but as the movie line goes, “Eventually, we’ll find the answer. Just like we always do. As the movie line goes, it seems that trying different things eventually leads to at least something close to an answer.

![]() Is there anything else you’d like to do with your job?

Is there anything else you’d like to do with your job?

My goal is to achieve the highest customer satisfaction score in 2024 by smoothly completing my current export orders. My personal plan is to increase my SPA score.

I’ve been with the North American Forwarding Operations team for over two years now, and I’ve always felt that everyone on the team is great, so even when the work is hard and you feel stressed at work, you quickly forget about it and enjoy your time here. I’d like to thank all my teammates and my team leader for creating the best team atmosphere!

![]() In one sentence, how would you describe the North America Forwarding Operation team to employees of Hyundai Glovis?

In one sentence, how would you describe the North America Forwarding Operation team to employees of Hyundai Glovis?

It’s Tanghuru. That’s because the individual fruit seeds have been sugar-coated into a team, and the synergy between them is incredible.

정리 편집실

2023.12.21